I have been working with several companies - trying to nail down a box size and type for my organic tea business. Chris Martin was the ONLY rep in all of the companies I reached out to who was responsive, helpful, and walked me through the entire process. It was an absolute pleasure to give my small business dollars to Plus Printers! I will provide another review after I receive my custom product!

When you select a packaging box, keep in mind that the outer appearance is not everything. The grade of cardboard thickness you choose impacts everything ranging from artwork printed upper surface, to protection, packaging durability, and the overall perception of the premium your brand holds in the market. That is something nobody would like, a worn box that tears apart at the seams, or disintegrates upon the slightest provocation.

When trying to gauge the appropriate material to use, pay attention to details like GSM (Grams per Square Meter), points, or even millimeters. For everyday use, the measurements lie within 1/6 and 1/3 of an inch. For more complex processes such as shipping sensitive objects, additional thickness is advisable. These stronger boxes provide much-needed security and peace of mind.

Settling on opting for a specific type of cardboard does not come easily. The packaging world has Styrofoam, bubble wraps, clamshells, foam in place, and much more of different kinds, thicknesses, blends, and weights. Most importantly, each type impacts the durability and shipping cost of the box.

This guide is also helpful in learning how to take measurements. After reading it, the material selection customization per product will be clear. Be it packing and pretending to ‘level up’ as you ship game space gifts, or outsmarting competition, the business edge you get from paying extra attention to packaging is hard to dispute. With delicate packaging trumping competitors, thoughtful cardboard selection grants an undisputed business advantage.

Let us explore further the significance of choosing the right cardboard thickness for your project!

How To Choose The Best Cardboard For Packaging?

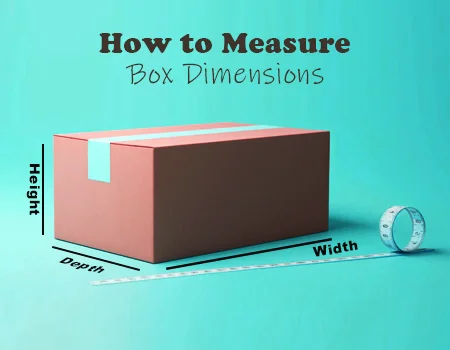

Choosing the right cardboard box dimensions ensures the protection of your product during shipping. The right size prevents unnecessary damage and optimizes packaging costs. Finding the right grade of cardboard for packaging needs is similar to perfecting a cupcake recipe. Making sure the strength, weight, thickness, and even the cost factor play to your advantage is truly the ideal scenario. Like it or not, packaging is far more than just putting a product in a box. It serves to protect, present, and preserve the item throughout shipping.

Understanding Cardboard Thickness

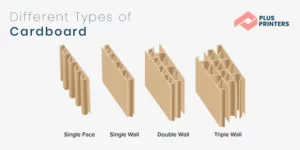

For weak, thin products, a smooth single-wall sheet will suffice. Lighter products will not need as much support, but thicker cardboard sheets with multiple layers are a must for fragile items. Typically, standard shipping box cardboard sheets are between 1/16 inch and 3/16 inch thick.

Bear these points in mind when selecting cardboard.

- Single-wall Cardboard: It is best suited for low-weight goods.

- Double-wall Cardboard: Double-wall cardboard is mid-level protection for heavier-sized products.

- Triple-wall Cardboard: It is heavy-duty cardboard best used for machinery and bulk items.

| Type of Cardboard | Thickness Range | Best Use |

| Single-Wall | 1/16 inch (1.5 mm) | Apparel, Books |

| Double-Wall | 3/16 inch (5 mm) | Electronics, Medium Appliances |

| Triple-Wall | 1/2 inch (12 mm) | Industrial Equipment, Bulk Shipping |

Choosing the wrong thickness can lead to packaging disasters, smashed cupcakes, anyone?

Assessing Product Weight and Shipping Needs

Not every cupcake has to be piled high with frosting. Not all products need extravagant packaging as well. Determine how heavy the item is first. Heavy items need sturdy cardboard boxes with multi-layered corrugated boards, while fragile products need cushioned F-flute or E-flute corrugated sheets to absorb shocks.

Factors to Consider:

Weight Bearing Capacity

Will the cardboard withstand other packages stacking on top during transit?

Edge Crush Resistance

Will the edges endure the pressure without crumbling?

Burst Strength

Will the cardboard burst when stressed suddenly?

Shipping fragile ceramics across state lines requires far more durability than shipping a lightweight shirt locally.

Aligning Thickness with Budget and Branding

Budget also matters in the design as pricing sulphate do with confectioners’ sugar. Thicker cardboard offers greater weather protection, which prevents damage, but costs more, while thinner sheets are budget-friendly and risky for fragile items.

Tips for Cost-Effective Choices:

- Thick sheets with a high GSM, like 300 or above, suit a luxury brand image.

- Bulk orders usually guarantee better pricing.

- Moderate durability with shipping expenses because heavy cartons equate to expensive freight.

Custom designed cartons with set-in dividers must be planned at the choosing stage. It’s easier and cost-effective to print visuals on smooth surfaces if the cardboard is thick enough to hold the ink without running.

Environmental Factors to Watch

Cardboard packaging’s worst enemies are temperature shifts and moisture. Weather can ruin moist cupcakes. Choosing environment-friendly liners is critical when shipping internationally.

Always confirm that the supplier holds an FSC certification. Also, ensure that materials labeled as recyclable do not increase the carbon footprint and are sustainable.

Choosing the Right Manufacturer

Always source from trusted manufacturers who issue testing certificates, such as edge crush tests or burst strength ratings. Customizable support makes exceptional packaging evident faster than mediocre designs and packaging.

Seek the guidance of a packaging specialist for:

- Machine and appliance industrial packaging.

- All your DIY and crafting needs.

- Custom-designed corrugated board packages.

Why Does Cardboard Thickness Matter?

Raw materials setup requires as much attention as baking a cake. Each selection needs to mix, layer and measure gently, enabling the desired finish.

Here is why the thickness of cardboard is important:

Protection of Product

Informing customers regarding restrictions on the packaging can lead to customer dissatisfaction and is inefficient. Every single form of packaging is aimed at protecting the enclosed product, and thick corrugated cardboard does an impressive job of protecting against damage. Absorbing shocks and impact during transportation and handling is made significantly easier with thick cardboard.

Secure Shipping

The complex requirements of features and dimensions lead to packaging that is inexpensive due to its simplicity. Employed for transporting items over long distances must not tear or warp easily without sharp corners. It must not fail under rough use, and sturdy framed boxes with weakened corners give strong cardboard boxes can disrupt optimization.

Cost Efficiency

Another strategy to reduce the price it all dents, thick, and sharp cardboard, does increases packaging and shipping weight, but greatly restrains and lessens everything, and almost delays product damage and loss while making cost efficiency surprisingly high.

Strength & Durability

Well-structured flutes with thick cardboard are more durable and can withstand broader, more pressure and external stress. Boxes with higher cardboard box weight tend to offer better protection against rough handling during transit. However, heavier boxes can also raise your overall shipping costs. They work best for stacking, carrying heavy items or rough riding shipping across the country, through worn terrain.

Environmental Shield

Surely it goes without saying that cardboard and other paper packages provide the last line of defence for a trade mark shielding products against humidity, moisture, heat and cold. Surely, the boxes that undergo the mechanical stress of changing weather need proper thickness to remain mechanically stable.

Customization & Branding

Better printed logos and graphics are often received with higher quality finishes. This can be achieved by increasing the thickness of the cardboard materials, and getting a business image print premium greatly enhances the appearance of your business.

Stackability

When optimal thickness is applied, your boxes become easily stackable during storage or transportation without collapsing the boxes or damaging the contents.

Even the most amazing packages will fail if no proper thickness is applied during delivery.

Tips to Choose The Right Cardboard Boxes

Selecting an appropriate cardboard box guarantees the safety of the product, its cost-effectiveness, and an impeccable appearance. To achieve the desired results for your packaging requirements, follow these helpful suggestions.

- Know Your Product’s Weight and Fragility

- Choose the Right Thickness (GSM or Ply)

- Pick the Perfect Size. Not Too Big or Small

- Select Box Type: Single, Double, or Triple Wall

- Consider Surface Finish for Printing and Branding

- Test with Samples Before Bulk Orders

- Check for Eco-Friendly Material Options

- Factor in Shipping and Handling Conditions

Different Methods of Measuring Cardboard Thickness

Getting the perfect ratio of frosting to cake, measuring cardboard thickness accurately requires precision! Luckily, there are several techniques available to measure thickness depending on one’s tools and needs.

Automatic Thickness Gauge

- How it works: Measures the amount of cardboard in sheets with speed and precision using a machine.

- Best for: Print and manufacturing industries dealing with large volumes of cardboard.

- Benefits: With no human input, automatic measuring guarantees uniformity.

Manual Thickness Gauge

- Tools Used: Micrometres or callipers are common tools for manual measuring.

- Best for: Smaller batch operations, hands-on projects, or checking large quantities.

- Benefits: Provides practical, manual control over the measurements, works well with custom or small-scale packaged goods.

Stack-and-Ruler Method

- How it Works: Stack several identical sheets of cardboard and compute their height using a ruler. Afterwards, divide it by the number of sheets.

- Best For: Any basic, non-methodical evaluations, for example, with workshops or crafting.

Understanding the thickness helps to fit the strength and durability requirements, aligning with the packaging needs.

Different Types of Cardboard and Their Thicknesses

Not all cardboards are the same. Cardboards are like cakes, which are constructed using several layers and toppings. The same goes for cardboards. They come in many variations, and each provides its degree of protection and strength.

Let us break it down:

Triple-Wall Cardboard

- Construction: Three layers of corrugated paper sandwiched between four linerboards.

- Standard Thickness: Almost 1/2 inch (roughly 12.7 mm).

- Perfect For: Industrial applications, automotive components, heavy machinery, or shipping in bulk.

- Weight: Much heavier as it is designed to withstand extreme pressure and rough conditions.

- Strength: Provides the greatest resistance to crushing, stacking, and impacts.

When it comes to extreme protection, triple-wall cardboard takes the crown and often goes unused unless necessary.

Double-Wall Cardboard

- Structure: Two fluted layers sandwiched between three linerboards.

- Typical Thickness: 3/16 inch, or around 4.5 mm.

- Ideal Use: Heavy or fragile items like electronics, ceramics and small appliances.

- Cardboard Weight: Double-wall cardboard boxes have a greater weight than single boxes, but it is still manageable.

- Strength: Excellent cushioning, puncture and stacking resistance.

Double-wall cardboard is selected on multiple occasions when dealing with shipments undergoing long travels or expecting rough handling.

Single Wall Cardboard

- Structure: One layer of corrugated fluted paper between two flat liner boards.

- Typical thickness: Approximately 1/16 inch or 1.5 mm.

- Ideal Use: Light-duty packaging for items like books, clothing and other retail goods.

- Cardboard Weight: Single-wall cardboards are lightweight and easy to handle and carry.

- Strength: Provides moderate protection against basic handling as well as short-distance shipping.

Single-wall cardboard is ideal for daily shipping requirements that do not require high-impact protection.

Personal Experience With The Cardboard Boxes

Based on our experience with shipping delicate electronics, selecting a box that is an improper box leads to significant destruction. We remember once when a single thin wall box we used got crushed during shipment. From that moment on, we switched to using double-wall boxes with foam padding. Since then, our product’s protection and presentation have been flawless.

Units to Measure Cardboard Thickness

Just like how to measure flour, sugar, and butter differently in baking (grams, cups, ounces), the thickness of cardboard can also be denoted differently. Here is a short list:

GSM (Grams per Square Meter)

- Meaning: quantifies the weight of the area per unit size of a surface.

- Range: A lightweight card starts at roughly 35 gsm, whilst sturdy duty corrugated cardboard can exceed 400 gsm.

- Best for: Used on paperboard and lightweight packages, as well as for marketing documents that require precision.

Points (PT)

- Meaning: 1 Point is equal to 1/1000 of an inch.

- Example: A board written 24 PT will have a thickness of 0.024 inches.

- Best for: Used on expensive packaging for business cards, fine printed boxes, then crafted for luxury.

Inches and Millimeters

- Meaning: Straightforward measurement of thickness in inches or millimeters.

Examples:

- 1/16 inch is approximately equal to 1.5 mm

- 1/8 inch is approximately equal to 3 mm

- 3/16 inch is approximately equal to 4.5 mm

- 1/4 inch is approximately equal to 6 mm

- Best for: Shipping boxes, industrial packaging, and sending packages internationally.

Picking the right unit guarantees that the outlines and boundaries of your packaging needs are precise. This unit optimally avoids any confusion, guaranteeing satisfaction to the client.

Conclusion

Cardboard thickness defines numerous conditions, some of which can be referred to as technical. It is the secret ingredient for flawless packaging, surrendering brand image, safety, and price.

The thickness of custom packaging has to be appropriate for the product. For lightweight items such as paper products or scarves, a single-wall board with a thickness of 3-4mm will suffice. On the other hand, electronics and heavier kitchen appliances benefit from the unparalleled protection offered by double or triple-walled cardboard boxes during transit.

Attention to detail is required at every stage, from selecting the materials to the last printing. For packaging, high-definition printing, reflective surfaces, and quality liners are paramount to ensure logos and colors stand out. Moreover, a balance between cost, strength, eco-friendliness, and cardboard’s environmental impact must all be factored in when choosing the material.

Selecting packaging options requires the same care as making gourmet cupcakes: with every ingredient and every layer, the interplay matters. Cupcake quality is represented in the sturdiness of the cardboard box, which is easy to ship and maintain product quality, while shrink wrapping offers a satisfying lift during unboxing to reveal what’s inside.

Packaging should not be viewed solely as an additional feature, but rather as a consideration of a product’s overall experience. To unbox is to receive a welcoming handshake and touch a first impression, all revealed with well-executed craftsmanship by Plus Printers, blending great materials with fast delivery that seamlessly meets the branding criteria.

Frequently Asked Questions

How thick is a standard box?

The ordinary shipping boxes are crafted from single-walled cardboard of thickness “1/8 inch (3 mm)”. Such a cardboard is both lightweight and durable, providing convenience during carrying and transportation.

How thick is single wall cardboard?

Single-wall cardboard usually ranges from 1/16 inch to 1/8 inch thick (approximately 1.5 mm to 3 mm), depending on the flute type (A, B, C, E, or F).

What is the difference between cardboard and boxboard?

To transport heavy goods, Cardboard is constructed from multi layered corrugated thick materials called liners and flute. Lightweight items such as cosmetics or cereal boxes are stored in a boxboard which is a single smooth ply paper board.

How thick is a boxboard?

Comparing it to heavy corrugated cardboard, boxboard is thinner and smoother because of its thickness, which generally falls anywhere between 0.010 to 0.030 inches (10 to 30 points).

See what reviewers are saying

Chris Martin was so helpful and responsive! We needed custom folders made and looked at various different companies, but Plus Printers ended up offering the best quality and price. This was our first time ordering, but Chris guided us through every step and even sent us videos of sample folders and mockups of our final product so we could proceed with confidence. Thank you Chris and Plus Printers, we will definitely re-order when we run out of this batch.

Company replied

We are very pleased with our packaging design! It was great working with Steven, I almost didn't work with Plus Printers because of their pricing but Steven went out of his way to try and negotiate prices with the sales department to fit our budget and offered us more budget-friendly packaging options as alternatives. Very responsive to my emails and made sure that our designs were how we wanted them! I look forward to working with them again soon!

wonderful service from a company that went beyond expectation to help my project get up and running smoothly. My sales rep, Paul, and the design team at Plus Printers made sure to have every detail in place and gave me a quote other companies could not touch! Lead times were accurate and updates for shipping were by far the most stellar i have yet to see. Thanks a milion!

Company replied

Replied to 100% of negative reviews

Typically replies within 1 week