I have been working with several companies - trying to nail down a box size and type for my organic tea business. Chris Martin was the ONLY rep in all of the companies I reached out to who was responsive, helpful, and walked me through the entire process. It was an absolute pleasure to give my small business dollars to Plus Printers! I will provide another review after I receive my custom product!

The use of cardboard as a material in packaging boxes is inexpensive and flexible, which makes it easier to work with. In addition, maintenance is straightforward, as it is eco-friendly as well. Considered cardboard box weigh does have advantages and disadvantages depending on the specific item. This shipping, storage, the overall cost, and the integrity of the goods are impacted. The article will discuss the measuring processes in detail and explain the weighing systems in steps.

Several properties increase the weight of a box which includes the material used, size and thickness of the specific box. A good example is 12×12, which is composed of a single wall and 6-pound weights. On the other hand, a double wall box can weigh 6 pounds and 30 ounces. Weight capacity is directly proportional to the wall thickness of the specific box. 0.5 pound minimum with over 30 maximum contributes towards the range of weighing. There is also standard filler material placed, which increases the estimated difficulty.

How to Calculate the Weight of a Cardboard Box?

Considering some important factors makes it easy to estimate the weight of a cardboard box. They are as follows.

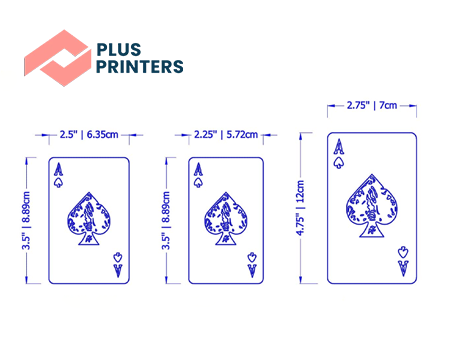

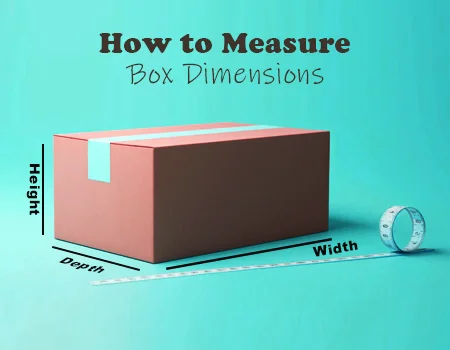

Box Dimensions

This is perhaps the most important factor for estimating the weight of a box’s dimensions. Bigger boxes will increase the use of materials, which directly increases the weight of the box. Measuring Box dimensions include length, breadth and height, which can be taken in inches or centimeters.

Material Type

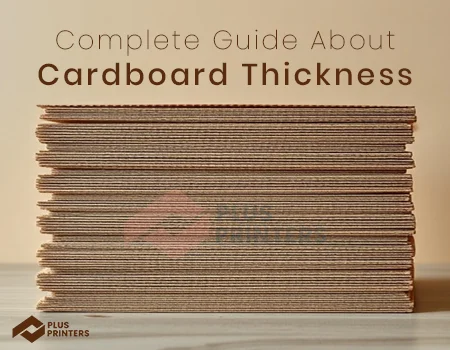

Cardboard boxes vary with the materials they are made of, such as single-wall, double-wall, or even triple-wall cardboard, and more layers increases the weight. Typically, double wall and triple wall boxes are heavier to provide more protection and support for the goods inside.

Box Thickness

As discussed with other shipping materials, additional thickness equates to additional weight. Standard thickness depends on the type of cardboard, and thicker cardboard is often used for heavy and fragile items.

Box Design

Reinforcements, flaps, handles and other unique features will add extra weight. Even though these features make the box stronger, they also increase the weight.

Filler Material

Some specific materials in a container may influence its weight. If boxes are secured with bubble wrap, packing peanuts, or any other type of filler, these items will contribute towards the weight as well.

Now, once you have the dimensions, type of material, and design ready, you can estimate the weight of the box using the basic weight estimating formula listed below:

Weight= Volume × Density

Where:

- Volume is found by multiplying the box’s length, width, and height in either cubic inches or cubic centimeters.

- Density means the material’s weight per unit of volume, which changes with cardboard type.

These days, you can even find box weight calculators online and use digital scales for rough estimations, which simplifies the task. Based on the specifications of your box, these tools estimate the weight quite accurately.

Average Weight of Cardboard Box Sizes

Estimating the average weight for different sizes of boxes is important while planning the storage space required or calculating the cost of shipping. The average weight for various sizes of cuboid shaped boxes, that are larger on one side, and rectangular prisms, is as follows:

- Extra-Extra-Large Boxes (50-60 inches):

- 48x60x48 inches: 30-36 pounds (14-16 kg)

- 54x54x54 inches: 36-42 pounds (16-19 kg)

- 60x60x60 inches: 42-48 pounds (19-22 kg)

- Extra-Large Boxes (40-50 inches):

- 36x48x30 inches: 18-22 pounds (9-11 kg)

- 40x40x36 inches: 22-26 pounds (11-13 kg)

- 48x48x42 inches: 26-30 pounds (13-14 kg)

- Large Boxes (30-40 inches):

- 24x36x18 inches: 10-12 pounds (5-6 kg)

- 30x30x20 inches: 12-15 pounds (6-7 kg)

- 36x36x24 inches: 15-18 pounds (7-9 kg)

- Medium Boxes (20-30 inches):

- 18x18x10 inches: 4-6 pounds (2-3 kg)

- 20x20x12 inches: 6-8 pounds (3-4 kg)

- 24x24x14 inches: 8-10 pounds (4-5 kg)

- Small Boxes (10-20 inches):

- 10x10x5 inches: 1-2 pounds (0.5-1 kg)

- 12x12x6 inches: 2-3 pounds (1-1.5 kg)

- 15x15x8 inches: 3-4 pounds (1.5-2 kg)

These values about the standard-sized boxes must be kept in mind the regard to the weight of the boxes, as it may vary depending on the cover material used as well as any embellishments which may be added to the box.

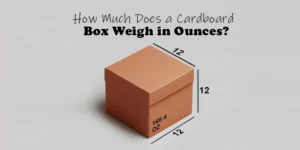

How Much Does a Cardboard Box Weigh in Ounces?

The different varieties of cardboard boxes differ from each other based on volume, materials used, their thickness, which in turn affects the weight and other factors. For the approximate calculation estimate, it is practical to work with some average weight and size figures. For this purpose, we set the baseline on box dimensions in inches and weight in ounces.

Consider, for example, a box with a bounding volume of a cube 12 inches on a side and made from a single wall of corrugated cardboard. Following this, the box would yield a total external volume of 12 inches cubed. Certain boxes of this kind would weigh something in the range from 64 – 96 ounces or 4-6 pounds. These are known in the industry as ‘single wall’ boxes. This kind of box is going to be lighter than the double wall versions, but all other factors remaining constant, this will not change the weight of the box.

A single wall box is going to weigh 64 ounces, which is 4 pounds.

A double wall box can hold up to 96 ounces or 6 pounds. This change is due to the added thickness of the boxes’ corrugated layers. These assumptions are just as valid for determining shipping or storage weight.

Formula:

Weight (in ounces) = (Length x Width x Height) / 166

Important Factors Affecting Weight

- Material: Single-wall vs. double-wall

- Dimensions: Larger boxes weigh more

- Reinforcements: Tape, staples, or added supports

Considerations that can assist you in managing your packaging needs include how much cardboard boxes weigh.

Standard Weights of Common Cardboard Boxes

Let’s explore the average weight of some of the common cardboard boxes that are differentiated by their size:

- Extra-Large Box (24” x 20” x 24”): 4 lbs to 5 lbs (1.81 kg to 2.27 kg)

- Large Box (24” x 18” x 18”): 2.5 lbs to 3 lbs (1.13 kg to 1.36 kg)

- Medium Box (18” x 14” x 12”): 1.5 lbs to 2 lbs (0.68 kg to 0.91 kg)

- Small Box (12” x 9” x 6”): 0.5 lbs to 0.75 lbs (0.23 kg to 0.34 kg)

Weight might change a little because of the design or material, but in general, these are just some guiding principles.

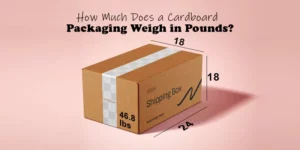

How Much Does a Cardboard Packaging Weigh in Pounds?

Estimating the weight of the cardboard packaging can prove to be particularly challenging when it comes to oversized or custom boxes. Take, for example, the weight of a single-wall 12x12x12” corrugated box. It is approximately 10.4 pounds during the shipping of goods. This figure can vary greatly due to different materials and various types of reinforcements used.

Standard corrugated cardboard packaging tends to be within 1-10 pounds, depending on the size and design. Also, oversized or extra-large boxes filled with products tend to cost around 30-40 pounds. Most importantly, estimating total weight for shipping also relies on DIM weight, which is calculated using the box’s volume.

All shipping companies, such as USPS, FedEx, and UPS, follow the same rules of Dimensional Weight Pricing. This practice states that the weight is determined by the actual weight of the box, the given/ estimated weight of the box, and the dimensions. This helps to reduce waste in both space and pricing while countering the issue of larger boxes being disproportionately underpriced for shipping costs.

As far as packaging materials go, possibly no one accepts cardboard quite like everyone else does. Cardboard is robust and versatile enough for nearly all products while also being cost-effective, which makes it a darling of nearly all industries. But asking yourself “What does a box weigh?” can, when put into perspective, save you time and money as well as improve some logistics processes that require some sort of weight calculations. If you are trying to ship a product, move, or prepare goods for long-term storage, getting a cardboard box is crucial. In this article, we will explore how box weight can be managed for both efficient cost and cost-effective packaging.

Formula:

Cardboard Box Weight= Length (L) x Width (W) x Height (H)/ 16

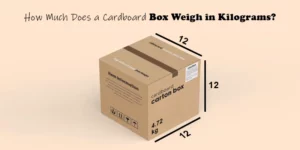

How Much Does a Cardboard Box Weigh in Kilograms?

Those who prefer the metric system, this is the section to pay attention to after covering the weight of a cardboard box in ounces. The general rule of thumb for converting the weight of items in pounds to kilograms is very simple: 1 pound equals 0.453592 kilograms.

Single-wall 12x12x12-inch cardboard boxes weigh in the 4-6 range, translating to approximately 1.8 to 2.7 kilograms. A double wall of the same dimensions will weigh between 2.7 and 3.5 kilograms.

Material and Size affect the box weight. Take, for example, a 28x12x17 cm box, which is approximately 1.7 kg (1700 grams) heavy. A significantly larger box, such as a 40x12x12 inch box, can go as high as 15.7 kg.

Weight Conversion Formula:

- Record the box size in inches.

- Translate to millimeters by multiplying by 25.4.

- Find the cubic centimeters and the cross-sectional area, and multiply the result by the height in cm.

- The box material’s density first has to be multiplied by the volume of the box to determine the weight, then the product will be the resulting number in grams, which then needs to be transformed into kilograms.

The box’s weight in kilograms will impact both shipping and storage costs, particularly in calculating DIM weight, a metric that combines size and weight for shipping purposes.

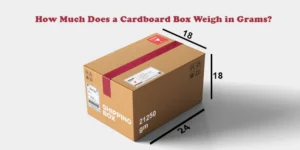

How Much Does a Cardboard Box Weigh in Grams?

The same reasoning as estimating weight in pounds or kilograms applies logic when estimating the weight of cardboard boxes in grams. To facilitate comprehension, let us further simplify and break this down into steps.

The estimated weight of a typical single-walled 12x12x12-inch box is around four pounds. In grams, this would be approximately 1814. A double wall version of the same box, however, might weigh between 2720 to 3400 grams, depending on how dense and thick the material is.

The smaller 6x6x6 box will weigh 180 grams for single wall boxes and 360 grams for double wall boxes. Now with larger boxes such as 18x18x18”, what about the 1360-1580 grams it would weigh for a single wall box, depending on the material’s thickness?

Quick Calculation:

- To convert from pounds to grams, multiply the weight in pounds by 453.592.

- All box weight calculations are also impacted by their dimensions. The larger the box, the more material they require, directly increasing the weight and cost.

Therefore, knowing the box weight in grams enables one to determine the storage solutions, shipping estimates, as well as the proper packaging needed.

Formula:

Weight= (Length x Width x Height) / 166

Factors Affecting Box Weight

Weight is determined by several different characteristics. Let’s explore the main contributors.

Materials: A Major Determinant

Cardboard differs in material strength, which impacts the weight of the box. Most boxes made out of cardboard are manufactured from a material called corrugated cardboard. This type has flutes for additional strength, which is fancifully enhanced with adhesives. Corrugated boxes also differ; they can be single wall, double wall or even triple wall. Their strength increases with the number of walls. Thus, adding layers increases the weight.

- Single-wall boxes are best suited for low-weight items.

- Double-wall boxes have greater strength and are used for heavyweight items.

- Triple-wall boxes are suited for extremely valuable goods because they need heavy-duty protection.

Size and Thickness Matter

The box’s size and thickness contribute to the amount of material utilized. Thus, calculating the weight.

Practical Tips for Managing Box Weight

Box weight must be managed to ship cost efficiently and effectively. If you are looking to sustain packaging integrity while also lightening the load, consider the following:

Use Lightweight Materials

Where suitable, use single-wall cardboard. It saves on weight while delivering reasonable safeguarding for lighter items.

Avoid Overpacking

Excessive packing or packing items too closely increases the box dimension and weight unnecessarily. Pack tightly but not obsessively.

Distribute Weight Evenly

When sending multiple items, ensure that the weight is balanced among the boxes to avoid one box being too heavy.

Use Multiple Smaller Boxes

Rather than using a single large box with contents, use smaller boxes to split the contents. This reduces weight as well as damage incurred to items.

Consider Moisture Control

The weight of cardboard boxes can result from moisture accumulation over time. Store your boxes in controlled environments to prevent absorbing moisture and weight.

Reinforce Only When Necessary

For larger items, it is sometimes necessary to reinforce boxes with tape or staples. It is essential that overdoing it doesn’t do any good; extra reinforcements undercut value by adding needless weight.

Bonus Tip: Adjusting the dimensions and height of the cardboard box according to your specifications guarantees that the box in question is fit for purpose, which means that there is no unnecessary weight and the need for padding materials and fillers is eliminated.

Conclusion

A variety of factors impact the weight associated with a given cardboard box. These are its intended use, the size of the box, and the shipping materials. Whether it’s shipping products, moving, or storing goods, weighing a cardboard box is necessary streamlined use of resources, time, and effort and is critical in fulfilling the requirements of transporting, shipping or relocating items.

Determining sizes such as 12x12x12 inches and 6x6x6, along with single-wall and double-wall boxes’ weight, empowers you to make thoughtful decisions regarding package contents. Exercise caution regarding DIM weight and other freight weight calculations to sidestep extra fees in shipping.

Alongside these, understanding the weight of the box contributes to optimizing storage space, enhancing safety and reliability during transport. The weight of the box, when regarded with storage solutions, planning for transportation, or overall logistics strategy, will consistently be critical.

Following some practical advice, such as picking the right material, not overpacking, and balancing the weight, can help you optimize the risk of packaging excess weight. Also, the weight handling in logistics terminology can improve your cost savings, operational efficiency, and overall performance in the supply chain.

For a sophisticated professional touch to your packaging needs, Plus Printers offers advanced cardboard boxes to fit your business requirements.

Frequently Asked Questions

How does the weight of a cardboard box impact shipping costs?

Shipping costs are directly influenced by the weight of a cardboard box. Heavier boxes tend to result in higher DIM weight as well as transport logistics, which increases their fees.

How does box size correlate with its weight?

Because of the amount of cardboard material that is needed, larger boxes tend to be heavier. In shipping, the selection of box size is very important in preventing unnecessary weight, thus, the correct size box must be selected.

Are Cardboard Boxes Recyclable?

Cardboard boxes are recyclable. Cardboard is produced from natural resources; thus, it can be converted into new products such as boxes, which makes them environmentally friendly.

How much does a cardboard box weigh in kg?

Depending on the material and thickness utilized, a single wall 12x12x12 inch cardboard box generally weighs between 1.8 to 2.7 kilograms, and for the double wall it is typically between 2.7 to 3.5 kilograms.

See what reviewers are saying

Chris Martin was so helpful and responsive! We needed custom folders made and looked at various different companies, but Plus Printers ended up offering the best quality and price. This was our first time ordering, but Chris guided us through every step and even sent us videos of sample folders and mockups of our final product so we could proceed with confidence. Thank you Chris and Plus Printers, we will definitely re-order when we run out of this batch.

Company replied

We are very pleased with our packaging design! It was great working with Steven, I almost didn't work with Plus Printers because of their pricing but Steven went out of his way to try and negotiate prices with the sales department to fit our budget and offered us more budget-friendly packaging options as alternatives. Very responsive to my emails and made sure that our designs were how we wanted them! I look forward to working with them again soon!

wonderful service from a company that went beyond expectation to help my project get up and running smoothly. My sales rep, Paul, and the design team at Plus Printers made sure to have every detail in place and gave me a quote other companies could not touch! Lead times were accurate and updates for shipping were by far the most stellar i have yet to see. Thanks a milion!

Company replied

Replied to 100% of negative reviews

Typically replies within 1 week