Who Are Shoe Box Manufacturers?

Shoe box manufacturers are firms that manufacture shoe packaging. These packaging options offer protection, storage and presentation. They concentrate on the premiumization, materials and branding to increase the retail show.

A full-service design and production team is ready to develop your custom shoe box packaging. Bespoke shoes have their own cultural or time-honored expectations that are worthy of being honored.

Why Are Shoe Box Manufacturers A Must-Have For Your Brand?

The shoe box manufacturer has a generator for the footwear industry. They package ideas into eternal, branded, stylish boxes and protect and display your shoes.

Shoe box manufacturers manufacture, design, print and produce packaging for all types of shoes. From stiff and cardboard to branded shoe boxes, they help brands land better retail placement and protect products in transit. These USA-based packaging companies combine creativity and innovation in their services, which results in inexpensive shoe boxes wholesale rates.

What Material Is Used by Shoe Box Manufacturers?

It is the quality of the materials that matters most for packaging. This magical combination of strength, sustainability, and presentation makes your brand’s shoes stand out while keeping them safe.

Cardboard Boxes for Reliable Protection

It is strong, recyclable and delivers exceptional strength for shipping and retail display.

Eco-Friendly Touch with Kraft Boxes

Natural Kraft packaging provides a rustic appearance. It is biodegradable, recyclable, and the ideal material for environmentally conscious footwear brands that want to accentuate sustainable values.

Rigid Boxes For Premium Look

Hard boxes have that luxury touch. Thicker, sturdier and frequently employed by high-end shoe brands in search of premium retail presentation.

What Are The Paper Stocks Used By Shoe Box Manufacturers?

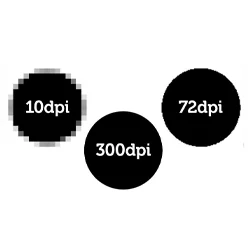

The paperstock used in custom boxes determines the texture and finishing of the boxes. It’s what dictates how good a print looks, how long it lasts and the way in which that printed object is going to feel.

Kraft Paper for Natural Appeal

Because it is eco-friendly and solid, kraft paper is universally used. It offers rich color printing with recyclable material.

Corrugated Cardboard for Extra Strength

To keep this from happening, our model uses corrugated cardboard so your shoes are safe while being transported. It cushions and protects against rain and dust.

Recycled Paperboard for Sustainability

Recycled paperboard supports eco-conscious production. Most USA shoe box companies use this material to minimize waste.

SBS and Premium Paperboard for Brand Showcase

Custom shoe box makers unanimously prefer SBS paperboard and premium paper stock. They have a nice printing surface, and the print is clear.

What Types and Shapes of Shoe Boxes Are There?

You could say that box styles set the tone of the unboxing. Each design offers a different way for your brand to express both its creativity and professionalism.

Classic Two-Piece Box Styles

Two piece shoe boxes consist of a separate lid and base. They are perfect for a simple but elegant packaging presentation.

Boxes with Hinged Lid for Simple Removal

Hinged lid boxes make it easy for customers to open and close the box. They open easily and are great for retail or high-end shoe boxes.

Custom Shapes for Brand Identity

Customized shoe box producers can also design a unique shape that emulates your brand character. They pop up on shelves and in online stores.

What Are the Sizes of Shoe Boxes for Men, Women and Kids?

If the shoe fits, so should its box. The shoe box supplier provides adjustable added length and width to match most shoe sizes.

Wider Men’s Shoe Boxes

Men’s shoes are generally wider and heavier. Therefore, shoe boxes are designed much stout in size for extra protection.

Shoe Box for Women

Women’s shoe packaging manufacturers create more stylish and practical packaging with a compact design suitable for use. The boxes are also sleek but still protective for heels or sandals.

Kids’ Shoe Boxes

Kids’ shoe boxes are more compact and adorned with prints in bright, fun colors. They offer great protection and are fun for both children and their parents.

Which Finishes Are The Best To Make Shoe Boxes Packaging More Attractive?

The finish determines the visual allure and feel of your packaging. They help transform plain boxes into attention-getting displays.

Types of Matte and Gloss finishes for Contemporary Looks

Matte finishes offer a subtle, smooth appearance, and gloss coatings provide a shiny, polished look that reveals printed designs.

Premium Look with Holographic and Foil Effects

Foil stamping and holographic coatings add to the brand’s premium quality appeal. They allow logos and details to pop.

Embossing and Debossing for Texture

Embossing means adding raised texture, and debossing presses designs into the box. Both lend an air of sophistication to personalized shoe box packaging.

What Types Of Printing Are Available?

The printing is what decides how your brand is displayed on each box. It’s a merger of color, technique and imagination.

CMYK and Pantone Accuracy in Printing

Vibrant full-color designs are produced by CMYK printing, but exact brand color matching is easily achieved, ensuring everything matches for professional identity.

Top and Flat Sheet Printing for Perfect Quality

We recommend offset printing for larger runs, and digital printing for short-run or custom print jobs with no setup cost.

Foil Stamping With a UV Spot Gloss for That Shine

Foil stamping and UV gloss accent logos and details provide shoe boxes with a high-end retail look.

How Much Does a Shoebox Cost?

Price is determined based on materials, size, finish and printing needs. Thousands: Wholesale shoe box distributors have pricing that is right for you.

Plus Printers offers low wholesale pricing that covers the cost of materials, manufacturing, printing, and shipping. If you are looking for a single prototype or you need overnight production runs, and you want the quality of a manufacturer.

How Do Different Industries Use Shoe Boxes?

Shoe boxes also serve an important purpose that extends beyond footwear. They play a critical role in packaging throughout fashion, retail and promotional industries.

Shoe boxes serve as the boot brands choose for product safety and branding. They are used in stores as well for a beautiful showcase and safe deliveries by E-commerce sellers. Shoe boxes are generally customized by apparel and sportswear brands for those seasonal launches.

Furthermore, they are also popular giveaways and promotional items with luxury boutiques and event organizers. Even many small businesses like wholesale shoe box packaging for branding continuity and customer retention.

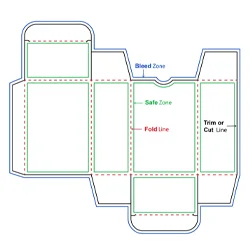

What Customizations Are Provided By Shoe Box Manufacturers?

Personalization animates your brand story. It sets your packaging apart, and it builds customer loyalty. Plus Printers offers complete control over every aspect, from the shape and color of the box to logos printed on it, as well as finishes. You can also select customized packaging, with foil logos, embossed brand names and window cutouts to display your product from the outside.

Furthermore, branded sleeves, inserts and templates are also available for efficient retail display. Whether you’re after a modern matte appearance or a glossy shine, we’ll ensure that everything fits in with your brand’s look and feel.

How Do Shoe Box Manufacturers Support Sustainability?

Green packaging is the way of the future. Manufacturers employ materials and techniques that shield both products and the planet.

Recycled Cardboard and Paper Materials

Recycled cardboard is a great way to recycle and still provide a long-lasting box. It is a thoughtful pick for eco-conscious companies.

Biodegradable and Compostable Options

Boxes that go in the compost, not the trash. Our shoeboxes are made from 85% post-consumer waste and biodegrade so that you can feel good about your purchase.

Sustainable Printing Practices

It is zero-waste, made possible by soy-based inks, FSC-certified paper, and green manufacturing.

What are the Sampling Options Offered by Shoe Box Manufacturers?

Sampling makes sure you will get the perfect quality that you need before bulk production. It’s what stands between a concept and perfection.

Prototype and Test Runs

With a prototype (mock-up) box, you can verify the size, colour and finish of your final order before it is made.

Why Choose Plus Printers?

Plus Printers is an innovative wholesale shoe box company in the market. Our passion from design through technical precision to sustainable products in premium quality.

Whether you are operating a small boutique or are a global shoe brand, we want to work with you. But our team takes on everything from design to delivery.

Place an order today and receive a free design sample to see how your custom shoe boxes turn out fast!